BIOMASS/RDF HANDLING

COMPLETE LINE FOR RDF PRODUCTION

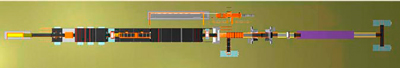

A professional 100% recycling technology for MSW (Municipal Solid Waste) in which we recycle and produce:

- All biodegradable fraction - full separation on a line (for extreamly short biocomposting process 3,5 days only)

- All incombustible fraction (mineral) - full separation on a line (inert fraction for landfill instead of sand)

- Secondary materials (eg.PET bottles, grass bottles) for recycling

- Ferrous and non-ferrous metals - automatic separation (for recycling)

- CI (Chlorine) - automatic separation (RDF requirements)

- Heavy fraction (eg.stones) - automatic separation

- Combustible fraction - full processing into RDF

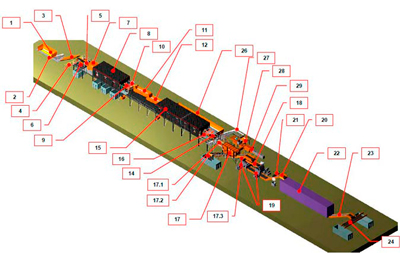

| Pos. | Item |

|---|---|

| 1 | Channel Steel Construction |

| 2 | Feeding chain conveyor – with support – Type PLK1200/6,0-4,5 |

| 3 | Rising-up conveyor – with support – Type PLZ1200/8,3 |

| 4 | Support (15 box) |

| 5 | Sorting conveyor - with support - Type PS1200/21,0 |

| 6 | Inspection Position |

| 7 | Bags opener RW1200 |

| 7.1 | Air-pressure preparation unit consisting compressor |

| 8 | Pre-Sorting cab (2x3) |

| 9 | Feeding rising-up conveyor – with support – Type PLZ1200/5,4 |

| 10 | Separator Fe – with support |

| 11 | Disk screen 0-30 mm |

| 12 | Disk screen 0-60 mm |

| 13 | Dust removing system |

| 14 | Sorting conveyor - with support - Type PS1200/26,0 |

| 15 | Sorting cab (2x5) |

| 16 | Separator Fe – with support |

| 17 | Aerodynamic separator – with support – Type SA1500 |

| 17.1 | Accelerating conveyor (aerodynamic separator) – with support – Type PP1400/4,6 |

| 17.2 | Heavy fraction conveyor (aerodynamic separator) – with support – Type PFC1200/7,3 |

| 17.3 | Light fraction conveyor (aerodynamic separator) – with support – Type PFL1400/8,6-3,0 |

| 18 | Reverse loading conveyor – with support – Type PRZ1400/4,4 |

| 19 | Shredder Lindner |

| 20 | Discharge chute shredder conveyor – with support – Type PRZ1400/11,0-7,5-2,0 |

| 21 | Separator Fe – with support |

| 22 | Dryer |

| 23 | Amounting drying conveyor – with support – Type PWSK1300/9,5-1,6 |

| 24 | Reverse loading conveyor – with support – Type PRZ1200/10,0 |

| 25 | Controlsystem |

| Pos. | Item |

| 26 | Channel Steel Construction |

| 27 | Feeding chain conveyor – with support – Type PLK1300/19,5-8,5-3,0 |

| 28 | Perforator - with support - Type P2-900 |

| 29 | Baler Press Type APK-091180/09 |

| 30 | Controlsystem |

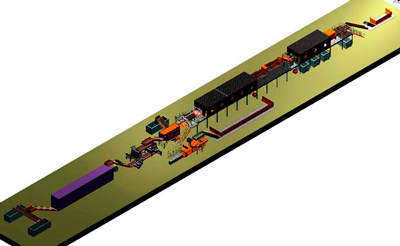

| Annual capacity | 40.000 Tm/year (tons per year) |

| Work system | 1 shift per day |

| Effective work time | 7 h/day (hour per day) |

| Annual working time limit | 287 days/yesr (day per year) |

| Capacity (per 1 shifts) | ca. 140,0 Tm/1 shift |

| Installed El.Power | 714,0 kW |

| Staff (total) | 29-39 per shift |

| Charger operator | 1 |

| Sorting operator | 22-32 |

| Press operator | 1 |

| Dryer operator | 1 |

| Logistic operator | 2 |

| Supervisor | 2 |

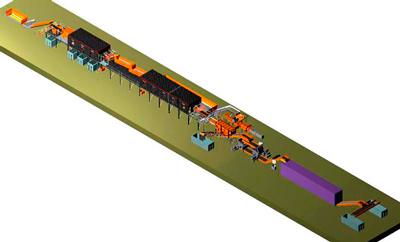

- Technological description of process: Processes: mechanical process of mixed municipal solid waste:

- Feeding waste with initial identification of problematic materials,

- Inspection sorting of problematic materials,

- Bags opener,

- Supervision during recycling (pre-sorting cabine) and collection secondary materials (eg., glass, paper-cardboard),

- Ferrous metals separation,

- Screening 0-30 [mm] fraction,

- Screening 0-60 [mm] fraction,

- Supervision during recycling (sorting cabine) and collection secondary materials (eg.PET, glass, paper-cardboard, ect.),

- Ferrous metals separation,

- Pneumatic separation of heavy fraction,

- Shredding/grinding,

- Ferrous metals separation,

- Dryers

- Lading on trucks/containers,

- Pressing the sorted secondary materials in horizontal balers.

Secon AFI

Secon AFI